Na farko, ba da batun taƙaitaccen gabatarwa ga aramid da PE.

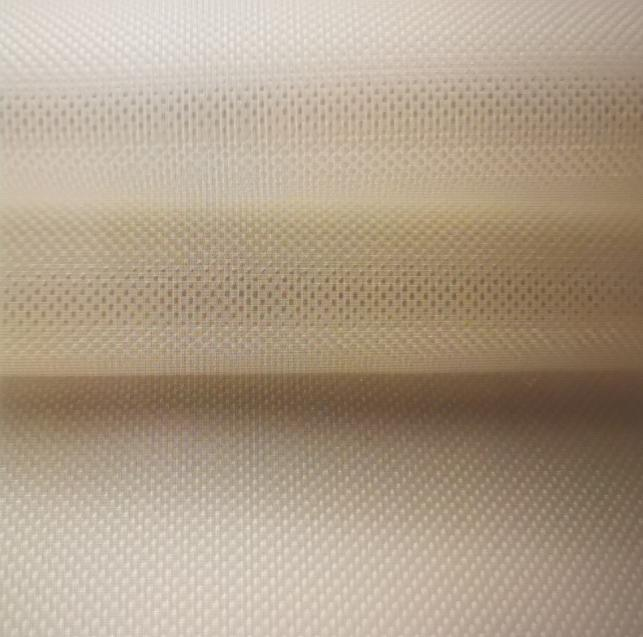

Aramid fiber kayan aiki Aramid, kuma aka sani da Kevlar (sunan sinadarai shine phthalamide) an haife shi a ƙarshen 1960s.Wani sabon nau'i ne na fiber na roba, wanda ke da tsayayyar zafin jiki, juriya na acid da alkali., Hasken nauyi, ƙarfin ƙarfi da sauran fa'idodi, an yi amfani dashi sosai a cikin kayan kariya na harsashi, gini da kayan lantarki da sauran su. filayen.

Amma aramid kuma yana da gazawa guda biyu:

1) zai ƙasƙanta lokacin da aka haɗu da haskoki na ultraviolet;yana da sauƙi don yin ruwa, ko da an adana shi a cikin busasshen wuri, zai sha danshi a cikin iska kuma a hankali ya yi ruwa.

Sabili da haka, abubuwan da ake sakawa na harsashi na aramid da rigar harsashi ba su dace da amfani da dogon lokaci ba a cikin yanayin ultraviolet mai ƙarfi da ɗanɗano, wanda zai rage aikin kariya da rayuwar sabis.Bugu da kari, rashin kwanciyar hankali da gajeriyar rayuwar aramid kuma yana iyakance kara aikace-aikacen aramid a fagen hana harsashi.

Farashin aramid mai inganci kuma ya fi na PE, wanda zai iya zama 30% zuwa 50% ƙari.A halin yanzu, samfuran hana harsashi ta amfani da aramid sun ragu sannu a hankali kuma sun fara maye gurbinsu da samfuran PE harsashi.Sai dai idan yana cikin yanayi na musamman ko yana da buƙatu na musamman, kamar yanayin zafi mai zafi na Gabas ta Tsakiya, ana ba da shawarar yin amfani da kayan aikin PE harsashi.

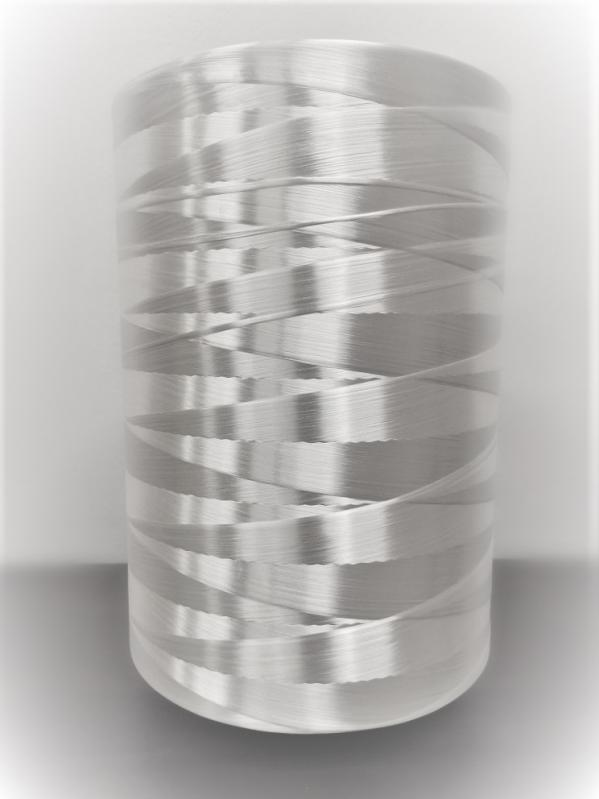

1. PE da aka ambata a baya a cikin PE fiber kayan aiki a zahiri yana nufin UHMW-PE, wanda shi ne matsananci-high kwayoyin nauyi polyethylene.Fiber ce mai girma da aka haɓaka a farkon shekarun 1980, kuma ana kiranta duniya a yau tare da fiber carbon da aramid.Uku high-tech zaruruwa.Jakunkuna na filastik da ake amfani da su a rayuwarmu ta yau da kullun samfuran polyethylene ne, waɗanda ke da babban kwanciyar hankali kuma suna da matuƙar wahalar ƙasƙanta, wanda ke haifar da gurɓataccen muhalli.Amma daidai ne saboda wannan sifa ta zama kayan aiki mai kyau don yin makamai na jiki.Bugu da ƙari, yana da halaye na ƙarancin zafin jiki, juriya na UV, da juriya na ruwa.

Dangane da tsaro da ƙananan harsasai masu sauri, UHMW-PE fiber's ballistic juriya yana da kusan 30% mafi girma fiye da na fiber aramid;

Dangane da tsaro da harsasai masu saurin gudu, ƙarfin harsashi na fiber UHMW-PE shine sau 1.5 zuwa 2 na fiber aramid, don haka a halin yanzu ana gane PE azaman mafi ingancin kayan kariya.

Koyaya, UHMW-PE shima yana da wasu gazawa: tsayin daka na zafinsa ya yi ƙasa da na aramid.Amfani da zafin jiki na samfuran harsashi na UHMWPE yana buƙatar sarrafawa a cikin 80 ° C (wanda zai iya saduwa da buƙatun zafin jiki na jikin mutum da kayan aiki - juriya na zafin jiki 55 ° C).Da zarar wannan zafin ya wuce, aikinsa zai ragu da sauri, kuma lokacin da zafin jiki ya kai 150 ° C ko sama, zai narke.A aramid harsashi kayayyakin har yanzu iya kula da barga tsari da kuma mai kyau kariya yi a cikin wani babban yanayin zafi na 200 ℃.Don haka, samfuran PE ba su dace da amfani da su a cikin yanayin zafi mai girma ba.

Bugu da ƙari, juriya mai raɗaɗi na PE ba ta da kyau kamar na aramid, kuma kayan aiki masu amfani da PE za su lalata sannu a hankali lokacin da aka ci gaba da matsa lamba.Sabili da haka, kayan aiki irin su kwalkwali waɗanda ke da siffofi masu rikitarwa kuma suna buƙatar jure wa matsa lamba na dogon lokaci ba za a iya yin su da PE ba.

Baya ga waɗannan halaye, farashin PE ya fi ƙasa da na aramid kamar yadda aka ambata a baya.

Gabaɗaya, PE da aramid suna da fa'idodi da rashin amfani.Duk da haka, an fi amfani dashi a zamanin yau don amfani da PE azaman Layer proof.Har yanzu yana da mahimmanci don zaɓar kayan aikin harsashi waɗanda suka dace da ku gwargwadon halin da kuke ciki.

Lokacin aikawa: Agusta-20-2021